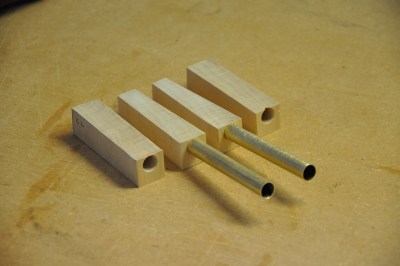

I took the easy (and heavier) road with my wing joiners...

I made the joiners from solid basswood and inserted brass tubing, instead of making my own Kevlar tubes.

I drilled 4 holes in the basswood and the cut between the holes.

I then used by belt and disk sander to bring the blocks to shape.

I left the brass tubes full-length so that I'd be able to use them to align the blocks when I glued up the mid and center panel spars.

For good or ill, I left my blocks a little thicker than the spar webs... for some reason I felt that I just needed a little more basswood around the holes. -- Probably a bad choice, but you'll notice the thicker spar at the joiner in all the wing panel pictures.

Once in place in the spars, the joiners got a double wrap of glass over the normal Kevlar thread wrap.

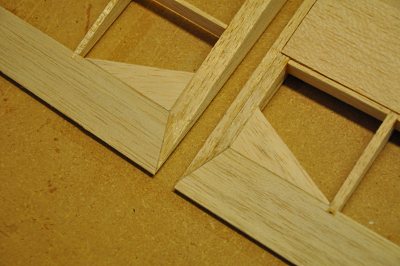

When it came to the trailing edge pin joiner, I felt that I didn't have as much material in the trailing edge as I needed to properly secure the pin.

I added some solid balsa wedges on both center and mid panels. This gave me a thicker dimension vertically to make my pin groove cuts.

I joined the center and mid panels using the main joiner rod and a quick clamp. I then flipped the panels over.

Using a flat stick wrapped in sandpaper, I notched a groove across the two panels at the appropriate location in the trailing edge.

Care must be taken to ensure that the groove is in alignment with the main wing rod.

I cut a brass tube and a carbon rod 2 3/4 inches in length.

I cut the brass tube in half, inserted the carbon rod into the tubes, and sealed up the tube ends with wax.

I placed the tubes into the groove, being careful to line up the break in the tubes with the edge of the panels.

Finally, using thickened epoxy, I glued the tubes in place.

Once the epoxy was set but not fully hardened, I carefully separated the two wing panels and removed the pin.

I set the panels aside to allow them to finish curing.

Now what remains is to glass in the end ribs on each of the panels.

I looked at the plans quite awhile before proceeding with glassing the end ribs on the mid and center panels.

What I came up with was that the fiberglass reinforcement acts as a cap on the end rib pairs to help transfer torsional loads and keep the ribs from splitting or peeling from the spar.

So I cut 16 1/2 inch strips - two for the top and bottom of each set of ribs.